Custom Laser Cutting Services — Fast, Accurate, Online

Online Sheet Metal Bending Service

Request a free sheet metal bending quote and receive expert design-for-manufacturability (DFM) feedback within 24 hours. Enjoy rapid turnaround with lead times as fast as 3–5 days.

- Bending Thickness Up to 60 mm

- Maximum Part Size 1.5 m x 1.5m

- Bend Angle +/- 1°

What is Sheet Metal Bending ?

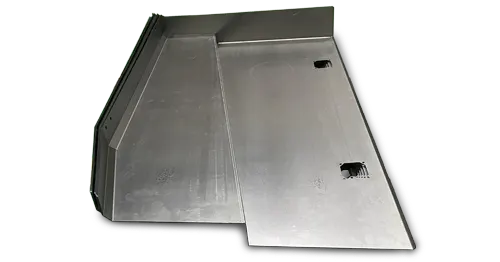

Sheet metal bending is a process in which force is applied to a flat sheet of metal to deform it into a specific shape. The metal is bent around a straight axis, changing its shape without affecting its thickness. This process is fundamental in creating a wide variety of components used in numerous industries, ranging from automotive to aerospace.

Why Choose Ours Sheet Metal Bending Service?

Our skilled engineering team leverages advanced metal bending technology and strict quality control processes to ensure every component meets the highest precision and performance standards.

With our advanced CNC bending equipment and optimized workflows, we deliver custom bent parts with exceptional speed and efficiency.

Our specialists support you at every step—from material selection to bending method—ensuring you achieve the best results for your project, every time.

Capabilities of Sheet Metal Bending Services

We offer premium sheet metal bending services, delivering high-precision, expertly finished components at highly competitive prices.

+/- 1°

Up to 800 tons

Up to 60 mm

1.5 m x 1.5m

Up to 7200 mm

5 business days or more

Design Guidelines

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in injection molding service

Minimum Bend Radius

2. For brittle materials (like aluminum or stainless steel), a larger radius may be needed.

Bend Orientation

Bend Allowance and K-Factor

2. Use the K-factor (typically between 0.3–0.5) to calculate accurate flat patterns.

Relief Cuts

Hole and Slot Placement

Flange Length

Consistent Bend Direction

Tolerances

Materials for Sheet Metal Bending

Overmolding technology represents a breakthrough in multi-material integrated manufacturing, offering a wide range of material pairing possibilities to meet diverse industrial needs.

Metals

Plastics

Woods

Applications of Sheet Metal Bending

Sheet metal bending is extensively utilized in numerous industries for its high precision, rapid processing, and efficient material usage, allowing for the creation of complex shapes with minimal waste.

FAQ

We provide high-precision plastic overmolding services that ensure seamless bonding, enhanced durability, and a perfect fit for complex multi-material parts.

We work with a wide range of materials including aluminum, stainless steel, mild steel, galvanized steel, copper, brass, and titanium.

Our equipment handles sheet metal thicknesses up to 10mm, depending on the material type and bend requirements.

We offer tight bending tolerances as low as ±0.2mm, and even tighter with CNC-controlled bending for critical parts.

Yes, our engineering team can review your drawings and suggest improvements to bend radius, material choice, and manufacturability.

Absolutely. We support one-off prototypes and small-batch runs, helping you validate designs before moving to mass production.

Springback is the material's tendency to return to its original shape after bending. We compensate by adjusting the bend angle based on material properties.

Yes, we accept STEP, IGES, DXF, and other common CAD formats for accurate quoting and production.

We provide sheet metal bending solutions for automotive, aerospace, electronics, industrial machinery, construction, and more.

Yes, we offer finishing options such as powder coating, anodizing, zinc plating, polishing, and brushing based on your needs.

Lead times vary by project size, but we typically deliver prototypes within 3–5 days and production orders in 7–15 business days.